Swiss CNC Machining For Aerospace Industry

Leave a CommentKernell’s Automatic Machining is an aerospace CNC machine shop specializing in the precision of aerospace parts. Our decades of experience and state-of-the-art technology allow us to offer an unmatched level of accuracy, quality, and reliability.

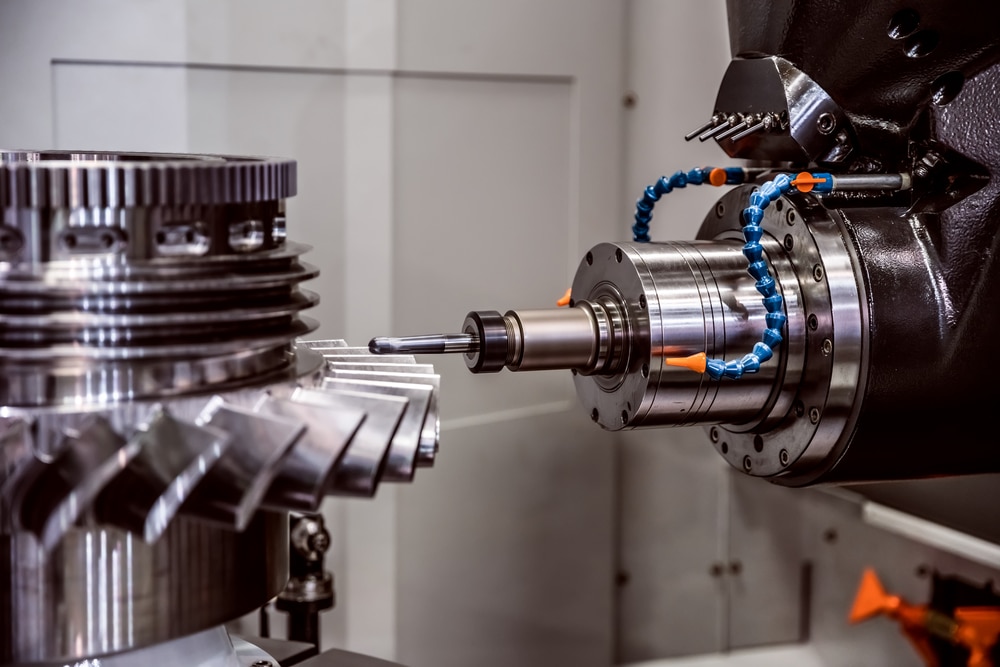

Our engineers use advanced Computer Numerical Control (CNC) systems to accurately create components and assemblies for the aerospace industry using aerospace CNC machining. With our skilled workforce and modern machinery, we can produce highly detailed parts with tight tolerances for any project in aerospace engineering.

How Swiss CNC Machining is Used in Aerospace Industry

Swiss CNC machining is a popular manufacturing technique used in the aerospace industry. This process uses computer-controlled machines to cut and shape materials into a desired product. The precision of Swiss CNC machining allows it to be used for intricate aerospace CNC machine parts that need to be manufactured with high accuracy and repeatability.

The speed and accuracy of this process make it highly efficient compared to traditional production methods such as:

- Milling

- Drilling

- Turning

Additionally, aerospace CNC machining can reduce lead times due to its ability to produce complex parts with minimal setup time required quickly. This makes it ideal for situations where time is of the essence, and high-precision components are needed.

Applications of CNC Machining for Aerospace Parts

This makes it ideal for aerospace applications such as aircraft components, turbine blades, rocket parts, and other complex structures. To understand better, here are some of its important uses in the industry.

- One of the most important applications of CNC machining for aerospace parts is creating components with complex shapes and surfaces. Using CNC machines, engineers can create intricate designs which cannot be replicated by traditional manufacturing techniques such as casting or milling.

- Components like turbine blades, engine manifolds, and fuel systems are all created using CNC machining.

- CNC machining also allows manufacturers to produce components with various materials, such as steel, aluminum, and titanium. This is important for aircraft parts as each material has unique properties that can be used to create the desired level of strength and durability for any given part.

- CNC machines are also ideal for producing large batches of identical parts efficiently– which is highly advantageous when manufacturing components on a mass scale.

Types of CNC Machining Processes

The aerospace sector utilizes three main types of CNC machining:

- Milling is a fast and reliable way to cut material into complex shapes using computer numerical control machines. The materials are milled precisely and can be combined with other techniques such as cutting, grinding, drilling, etc. Milling is used when creating intricate patterns or detailed structures where multiple tools or operations may be needed.

- Turning creates axles, shafts, bolts, and other parts with round edges or surfaces. It can also be combined with other machining techniques, such as drilling or cutting, to create complex shapes or patterns.

- Drilling is an essential part of CNC machining for aerospace components because it allows engineers to measure holes and slots according to exact specifications precisely. Engineers can quickly create identical hole sizes with excellent accuracy and repeatability by controlling the feed rate and depth of the drill bit on a CNC machine.

Kernell’s Automatic Machining for Aerospace Industry

From faster machining times to improved accuracy and precision, Kernell’s Automatic Machining technology is designed to revolutionize the Aerospace industry. Our advanced robotic systems can be tailored to your specific needs, streamlining production and saving on costs.

We always aim to make automation available in every corner of the aerospace sector. Contact us today if you need help finding a reliable way to mechanicalize your needs.

Swiss CNC Machining for the Medical Industry

Leave a CommentKernell’s Automatic Machining provides superior machining services. Our in-house capabilities include cutting-edge technology and equipment that can produce outstanding products. One of our core services is Swiss CNC Machining, which numerous industries require for specific applications. And one of them is the medical sector.

Our team comprises expert engineers and technicians ready to work on any challenge with our sophisticated process. We understand that the medical industry is very demanding. Each product, part, and component must meet industrial standards for various uses. That’s why we deploy leading-edge and reliable equipment to ensure the best result for medical applications.

Swiss CNC Machining for the Medical Industry

Swiss CNC Machining can create complex and intricate parts with fine details necessary for the medical field. It s the perfect solution because it uses a computer numerical control unit. So it allows for pre-programmed instructions. Plus, it will enable more tooling features to perform more operations on a single piece at once.

Our team always pays attention to the smallest details, ensuring each product meets your specifications. With Swiss CNC machining an excellent method to fabricate small parts and components, the medical industry has chosen it as one of the most reliable methods to achieve the products they need for various medical applications.

Benefits of Swiss CNC Machining for medical industry components:

- Create complex parts: One of the benefits of Swiss CNC machining is that it can create complex parts. As mentioned above, it allows for more tooling features. Therefore, more delicate parts can be achieved.

- Incredible accuracy: Another reason to choose Swiss CNC machining for medical environments is that the results are accurate and have little to no error. So you don’t need to worry about mistakes or inconsistencies.

- High repeatability: With Swiss CNC machining, you can achieve a high level of repeatability with each product. It ensures that the components are consistent and meet your requirements every time.

- Efficient: Finally, Swiss CNC machining is also very efficient. Since it uses pre-programmed instructions to achieve your desired cuts, manual labor isn’t required. One operator can work on several Swiss CNC machines at once.

Outstanding Capabilities of Swiss CNC Machining

Kernell’s Automatic Machining strives to perfect each part and component through our Swiss CNC machining technique. We have the equipment, tools, and devices to meet our client’s needs and requirements. So we can manufacture products with high precision and detail in a single operation.

We’re capable of adhering to your tight tolerances or complex geometries while delivering near-perfect products in a short amount of time. Customer success is our primary goal: to become a reliable go-to machining service provider you can trust every time.

In the medical industry, we understand how crucial it is to produce results of the highest standards. So whether you need standard or custom solutions, Swiss CNC machines can deliver the best results for your medical needs.

Swiss CNC machining capabilities by Kernell’s Automatic Machining:

- 050’’ to 1.250’’ in diameter

- Lengths up to 20″

- Tight tolerances: ±0.0005’’ diameter, 0.001’’ total length, and 0.005’’ total straightness

- Materials: Copper, brass, aluminum, nylon, stainless steel, PEEK, carbon steel, steel alloys, and rigid polymers

- ISO 9001:2015 Quality Management Systems certification

- Custom add-ons and secondary services are available

Choose Kernell’s Automatic Machining to Achieve Quality Parts for Medical Applications

We have the knowledge and expertise to ensure we design and manufacture quality outcomes for your project. So if you have any special requests, demands, concerns, or questions, don’t hesitate to contact us today. We’re here to guide you through the entire process so that we can find a winning solution. Or request a quote, and we can work on your project immediately.