Kernell’s Automatic Machining is an aerospace CNC machine shop specializing in the precision of aerospace parts. Our decades of experience and state-of-the-art technology allow us to offer an unmatched level of accuracy, quality, and reliability.

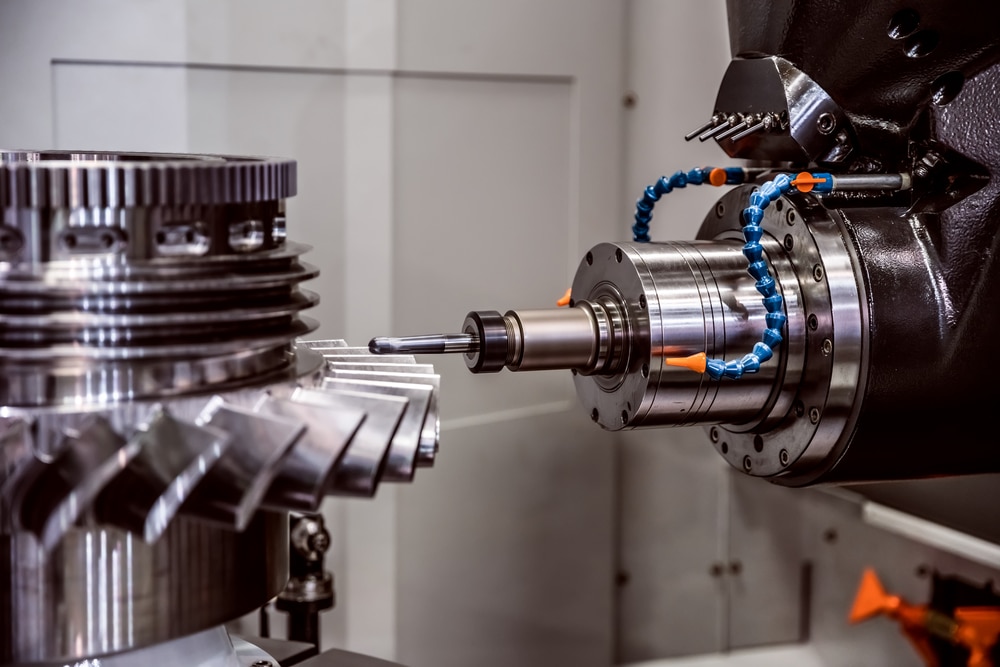

Our engineers use advanced Computer Numerical Control (CNC) systems to accurately create components and assemblies for the aerospace industry using aerospace CNC machining. With our skilled workforce and modern machinery, we can produce highly detailed parts with tight tolerances for any project in aerospace engineering.

How Swiss CNC Machining is Used in Aerospace Industry

Swiss CNC machining is a popular manufacturing technique used in the aerospace industry. This process uses computer-controlled machines to cut and shape materials into a desired product. The precision of Swiss CNC machining allows it to be used for intricate aerospace CNC machine parts that need to be manufactured with high accuracy and repeatability.

The speed and accuracy of this process make it highly efficient compared to traditional production methods such as:

- Milling

- Drilling

- Turning

Additionally, aerospace CNC machining can reduce lead times due to its ability to produce complex parts with minimal setup time required quickly. This makes it ideal for situations where time is of the essence, and high-precision components are needed.

Applications of CNC Machining for Aerospace Parts

This makes it ideal for aerospace applications such as aircraft components, turbine blades, rocket parts, and other complex structures. To understand better, here are some of its important uses in the industry.

- One of the most important applications of CNC machining for aerospace parts is creating components with complex shapes and surfaces. Using CNC machines, engineers can create intricate designs which cannot be replicated by traditional manufacturing techniques such as casting or milling.

- Components like turbine blades, engine manifolds, and fuel systems are all created using CNC machining.

- CNC machining also allows manufacturers to produce components with various materials, such as steel, aluminum, and titanium. This is important for aircraft parts as each material has unique properties that can be used to create the desired level of strength and durability for any given part.

- CNC machines are also ideal for producing large batches of identical parts efficiently– which is highly advantageous when manufacturing components on a mass scale.

Types of CNC Machining Processes

The aerospace sector utilizes three main types of CNC machining:

- Milling is a fast and reliable way to cut material into complex shapes using computer numerical control machines. The materials are milled precisely and can be combined with other techniques such as cutting, grinding, drilling, etc. Milling is used when creating intricate patterns or detailed structures where multiple tools or operations may be needed.

- Turning creates axles, shafts, bolts, and other parts with round edges or surfaces. It can also be combined with other machining techniques, such as drilling or cutting, to create complex shapes or patterns.

- Drilling is an essential part of CNC machining for aerospace components because it allows engineers to measure holes and slots according to exact specifications precisely. Engineers can quickly create identical hole sizes with excellent accuracy and repeatability by controlling the feed rate and depth of the drill bit on a CNC machine.

Kernell’s Automatic Machining for Aerospace Industry

From faster machining times to improved accuracy and precision, Kernell’s Automatic Machining technology is designed to revolutionize the Aerospace industry. Our advanced robotic systems can be tailored to your specific needs, streamlining production and saving on costs.

We always aim to make automation available in every corner of the aerospace sector. Contact us today if you need help finding a reliable way to mechanicalize your needs.