Have you heard of Swiss CNC machining? It’s a revolutionary manufacturing process changing how things are made. With this fantastic technology, manufacturers can cut and mold materials into intricate shapes with high precision. So whether you’re looking to create small parts or larger products, as additions or improvements to components or assemblies, chances are Swiss CNC machining could be precisely what you need.

Let’s learn what a CNC swiss machine is and some real-world examples of applications in different industries. It’ll help you understand how it can benefit you and your projects in the future!

What Does Swiss Machining Mean?

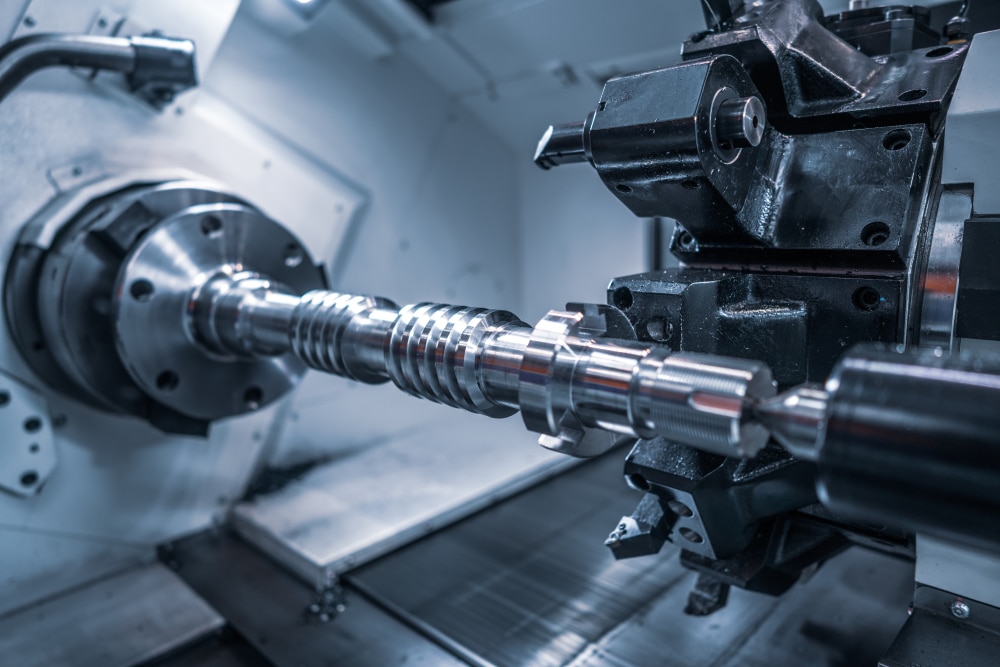

CNC swiss machining is a cost-effective and ultra-precise manufacturing process that can machine turned parts using a swiss CNC machine. CNC means computer numerical control, which refers to a computer unit that can control the machine with more tooling sets. So the equipment can perform different operations on the same piece due to the computer’s increased direction.

A CNC swiss screw machine has the same process. However, screw machining primarily involves removing material from a rotating piece. Furthermore, using a swiss machine CNC offers more benefits than other CNC manufacturing processes.

The Benefits of Using Swiss CNC Machines

Opting for Swiss CNC Machining instead of CNC swiss screw machining offers many advantages. It’s a prevalent technique that many manufacturers use today since its results are accurate and fast. Plus, it’s highly flexible.

Other benefits of Swiss CNC Machining are as follows:

- More tooling fixtures: More tooling fixtures are available, which can offer a double spindle feature.

- Time-saving: The more fixtures available, the more time the operator can save since it can create different cuts in one piece while only controlling a computer.

- Ideal for large-scale projects: Once the machine is pre-programmed and oriented with the desired pieces, it can run one part after the other. Thus, it is an ideal choice for large-scale projects with multiple parts requiring congruent measurements. Plus, one operator can supervise several machines at once.

- Do more precision work: Swiss CNC machining can do more precise work due to the tight, close quarters of the collet, tooling, and workpiece. So, it allows manufacturers to achieve their desired outcome.

These benefits make it an ideal option for small parts requiring precise measurements and intricate details. Many industries opt for swiss CNC machining compared to other methods.

Common Applications For Parts Made Through CNC Swiss Machining

In the industrial sector, most small parts are made through CNC swiss machines due to their low-cost factor. Plus, the process is faster. So it’s perfect for large-volume runs. Furthermore, it’s used in different sectors, such as IT, Agriculture, Automotive, Medical, Power, Consumer Electronics, and Aerospace.

Some of the most common applications are as follows:

- Surgical screws

- Medical devices

- Dental implants

- Scalpel

- Forceps

- Glasses

- Switches

- Connectors

- Springs

- Bearings

- Hubs

- Terminals

- Catalytic converters

- Mufflers

- Braces

- Splints

Many other specific products can be created and molded with the help of a swiss machine CNC. Above are just a few examples to give you an idea of what it can do.

Why Is It Ideal for Custom Solutions?

Since only some have the exact requirements, most manufacturers offer customized solutions using a CNC swiss machine. It’s the best option since they can get the specifications and design the customer wants and pre-program it onto the CNC unit. Plus, most manufacturers can adhere to the tight tolerances required for a specific item.

Choose Kernell’s Automatic Machining for Your CNC Swiss Machining Needs

We understand that every client is different. So we ensure that we have the best services to deliver quality products that exceed your expectations using a Swiss CNC Machine.

But if you have any questions or concerns, please contact us today. Or you can request a quote, and we’ll start your project immediately.