Category Archive: Blog

In the high-stakes, high-performance world of military applications, only the best, most precise components will suffice. The defense industry relies heavily on machining services that can deliver products with exceptional accuracy, durability, and resilience. Swiss CNC military machining, a process renowned for its precise, efficient production capabilities, is instrumental in manufacturing components for military use. Kernell’s Automatic Machining provides exemplary Swiss military CNC machining services, proving instrumental in creating military-grade parts with unparalleled precision.

What is Swiss CNC Machining?

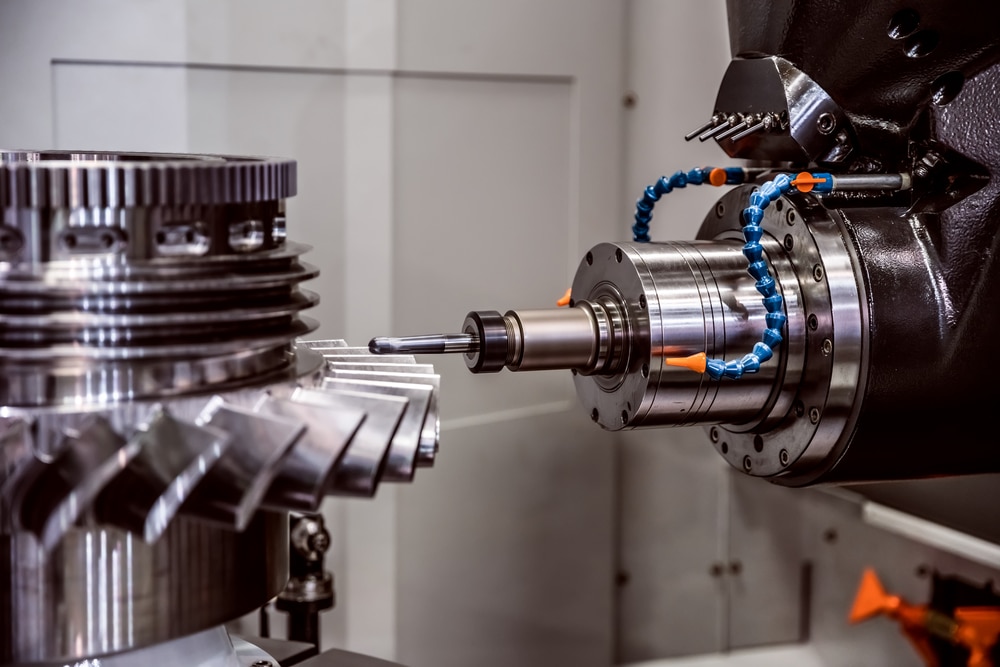

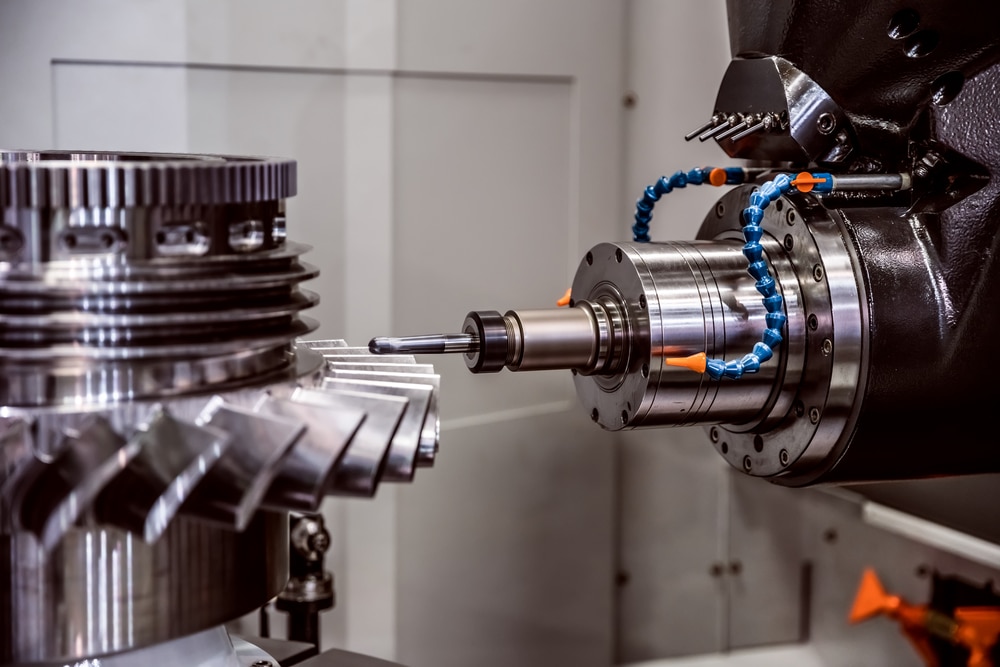

Swiss CNC machining, also known as Swiss-type lathe or Swiss automatic lathe, is a unique precision manufacturing technique that excels at producing small parts quickly and accurately. Unlike traditional CNC machines that operate along the X and Y axes, Swiss CNC machines introduce an additional dimension: rotation around the Z-axis. This results in a total of five rotational capabilities, making Swiss CNC machines more versatile and accurate than their counterparts.

The process begins by feeding bar stock through a guide bushing, which provides robust support to the material as it moves into the tooling area of the machine. This tight hold allows for greater stability and precision during machining. As only the portion being machined advances into the tooling area, this innovative design prevents unnecessary movements, enhancing the accuracy of the output.

Swiss CNC machines can perform several operations simultaneously, a stark contrast to traditional lathes, which typically conduct one operation at a time. Despite their name, Swiss machines are not restricted to turning tasks alone; they are equally efficient at producing complex pieces that bear no turned surfaces at all.

Swiss CNC Machining: A Game Changer in Military Applications

Military-grade materials require machining processes with extraordinary precision and capabilities—something that Swiss military CNC machining is renowned for. Many military armaments, from weapons to vehicles, consist of materials only Swiss military CNC machines can adequately construct due to their unique five-axis rotational capability.

From the production of high-precision components for guided missile systems to the manufacturing of complex casings and housings for military aircraft, Swiss CNC machining for military demonstrates its versatility and efficiency. It also plays a critical role in creating intricate parts for robotic weapons systems and other military applications. The precision and durability offered by Swiss military CNC machining allow these parts to withstand the extreme conditions typical of military environments.

Advantages of Swiss CNC Machining for Military Applications

Swiss CNC military machining provides numerous benefits for military applications, including:

Enhanced Precision and Accuracy

Swiss military CNC machining ensures extraordinary precision, even when dealing with micro-sized parts, thanks to the tight hold of the workpiece right next to the point of operation, thus reducing any chance of deviation.

Complex Parts Production

The robust support provided during the machining process allows Swiss machines to create intricate parts with thin walls, delicate features, and deeper cuts. This is a unique capability, unmatched by other conventional machines.

Rapid Production

Swiss CNC machines can significantly reduce cycle time, often churning out up to 30 parts per hour. This speed is much higher compared to traditional CNC machines, making Swiss CNC military machining ideal for mass production.

Cost Efficiency

Swiss CNC machines generate parts with such precision that they often eliminate the need for secondary operations. This reduction leads to cost savings and delivers ready-to-ship parts, increasing overall production efficiency.

Quality Assurance

Kernell’s Automatic Machining prioritizes quality. We leverage our Swiss CNC machines to produce components to exact specifications, ensuring high-quality output for military applications where no margin for error can be afforded.

Swiss Military CNC Machining at Kernell’s Automatic Machining

Kernell’s Automatic Machining brings Swiss CNC machining expertise to the forefront of military applications. With a firm commitment to accuracy, efficiency, and quality, Kernell’s leverages its advanced Swiss CNC machines to create robust, durable, and high-precision components that meet the stringent demands of military-grade materials. Our capability to work with a range of materials, from aluminum and stainless steel to titanium and high-performance plastics, positions us as the go-to provider for military Swiss CNC machining services.

When it comes to manufacturing components for military projects, Kernell’s is your reliable source for Swiss CNC machined parts. Our proven track record in providing Swiss CNC military machining services is testament to our commitment to excellence. Don’t waste any more time searching, contact Kernell’s Automatic Machining today and let us start working on your next big project immediately.

Kernell’s Automatic Machining is an aerospace CNC machine shop specializing in the precision of aerospace parts. Our decades of experience and state-of-the-art technology allow us to offer an unmatched level of accuracy, quality, and reliability.

Our engineers use advanced Computer Numerical Control (CNC) systems to accurately create components and assemblies for the aerospace industry using aerospace CNC machining. With our skilled workforce and modern machinery, we can produce highly detailed parts with tight tolerances for any project in aerospace engineering.

How Swiss CNC Machining is Used in Aerospace Industry

Swiss CNC machining is a popular manufacturing technique used in the aerospace industry. This process uses computer-controlled machines to cut and shape materials into a desired product. The precision of Swiss CNC machining allows it to be used for intricate aerospace CNC machine parts that need to be manufactured with high accuracy and repeatability.

The speed and accuracy of this process make it highly efficient compared to traditional production methods such as:

Additionally, aerospace CNC machining can reduce lead times due to its ability to produce complex parts with minimal setup time required quickly. This makes it ideal for situations where time is of the essence, and high-precision components are needed.

Applications of CNC Machining for Aerospace Parts

This makes it ideal for aerospace applications such as aircraft components, turbine blades, rocket parts, and other complex structures. To understand better, here are some of its important uses in the industry.

- One of the most important applications of CNC machining for aerospace parts is creating components with complex shapes and surfaces. Using CNC machines, engineers can create intricate designs which cannot be replicated by traditional manufacturing techniques such as casting or milling.

- Components like turbine blades, engine manifolds, and fuel systems are all created using CNC machining.

- CNC machining also allows manufacturers to produce components with various materials, such as steel, aluminum, and titanium. This is important for aircraft parts as each material has unique properties that can be used to create the desired level of strength and durability for any given part.

- CNC machines are also ideal for producing large batches of identical parts efficiently– which is highly advantageous when manufacturing components on a mass scale.

Types of CNC Machining Processes

The aerospace sector utilizes three main types of CNC machining:

- Milling is a fast and reliable way to cut material into complex shapes using computer numerical control machines. The materials are milled precisely and can be combined with other techniques such as cutting, grinding, drilling, etc. Milling is used when creating intricate patterns or detailed structures where multiple tools or operations may be needed.

- Turning creates axles, shafts, bolts, and other parts with round edges or surfaces. It can also be combined with other machining techniques, such as drilling or cutting, to create complex shapes or patterns.

- Drilling is an essential part of CNC machining for aerospace components because it allows engineers to measure holes and slots according to exact specifications precisely. Engineers can quickly create identical hole sizes with excellent accuracy and repeatability by controlling the feed rate and depth of the drill bit on a CNC machine.

Kernell’s Automatic Machining for Aerospace Industry

From faster machining times to improved accuracy and precision, Kernell’s Automatic Machining technology is designed to revolutionize the Aerospace industry. Our advanced robotic systems can be tailored to your specific needs, streamlining production and saving on costs.

We always aim to make automation available in every corner of the aerospace sector. Contact us today if you need help finding a reliable way to mechanicalize your needs.

Kernell’s Automatic Machining provides superior machining services. Our in-house capabilities include cutting-edge technology and equipment that can produce outstanding products. One of our core services is Swiss CNC Machining, which numerous industries require for specific applications. And one of them is the medical sector.

Our team comprises expert engineers and technicians ready to work on any challenge with our sophisticated process. We understand that the medical industry is very demanding. Each product, part, and component must meet industrial standards for various uses. That’s why we deploy leading-edge and reliable equipment to ensure the best result for medical applications.

Swiss CNC Machining for the Medical Industry

Swiss CNC Machining can create complex and intricate parts with fine details necessary for the medical field. It s the perfect solution because it uses a computer numerical control unit. So it allows for pre-programmed instructions. Plus, it will enable more tooling features to perform more operations on a single piece at once.

Our team always pays attention to the smallest details, ensuring each product meets your specifications. With Swiss CNC machining an excellent method to fabricate small parts and components, the medical industry has chosen it as one of the most reliable methods to achieve the products they need for various medical applications.

Benefits of Swiss CNC Machining for medical industry components:

- Create complex parts: One of the benefits of Swiss CNC machining is that it can create complex parts. As mentioned above, it allows for more tooling features. Therefore, more delicate parts can be achieved.

- Incredible accuracy: Another reason to choose Swiss CNC machining for medical environments is that the results are accurate and have little to no error. So you don’t need to worry about mistakes or inconsistencies.

- High repeatability: With Swiss CNC machining, you can achieve a high level of repeatability with each product. It ensures that the components are consistent and meet your requirements every time.

- Efficient: Finally, Swiss CNC machining is also very efficient. Since it uses pre-programmed instructions to achieve your desired cuts, manual labor isn’t required. One operator can work on several Swiss CNC machines at once.

Outstanding Capabilities of Swiss CNC Machining

Kernell’s Automatic Machining strives to perfect each part and component through our Swiss CNC machining technique. We have the equipment, tools, and devices to meet our client’s needs and requirements. So we can manufacture products with high precision and detail in a single operation.

We’re capable of adhering to your tight tolerances or complex geometries while delivering near-perfect products in a short amount of time. Customer success is our primary goal: to become a reliable go-to machining service provider you can trust every time.

In the medical industry, we understand how crucial it is to produce results of the highest standards. So whether you need standard or custom solutions, Swiss CNC machines can deliver the best results for your medical needs.

Swiss CNC machining capabilities by Kernell’s Automatic Machining:

- 050’’ to 1.250’’ in diameter

- Lengths up to 20″

- Tight tolerances: ±0.0005’’ diameter, 0.001’’ total length, and 0.005’’ total straightness

- Materials: Copper, brass, aluminum, nylon, stainless steel, PEEK, carbon steel, steel alloys, and rigid polymers

- ISO 9001:2015 Quality Management Systems certification

- Custom add-ons and secondary services are available

Choose Kernell’s Automatic Machining to Achieve Quality Parts for Medical Applications

We have the knowledge and expertise to ensure we design and manufacture quality outcomes for your project. So if you have any special requests, demands, concerns, or questions, don’t hesitate to contact us today. We’re here to guide you through the entire process so that we can find a winning solution. Or request a quote, and we can work on your project immediately.

Have you heard of Swiss CNC machining? It’s a revolutionary manufacturing process changing how things are made. With this fantastic technology, manufacturers can cut and mold materials into intricate shapes with high precision. So whether you’re looking to create small parts or larger products, as additions or improvements to components or assemblies, chances are Swiss CNC machining could be precisely what you need.

Let’s learn what a CNC swiss machine is and some real-world examples of applications in different industries. It’ll help you understand how it can benefit you and your projects in the future!

What Does Swiss Machining Mean?

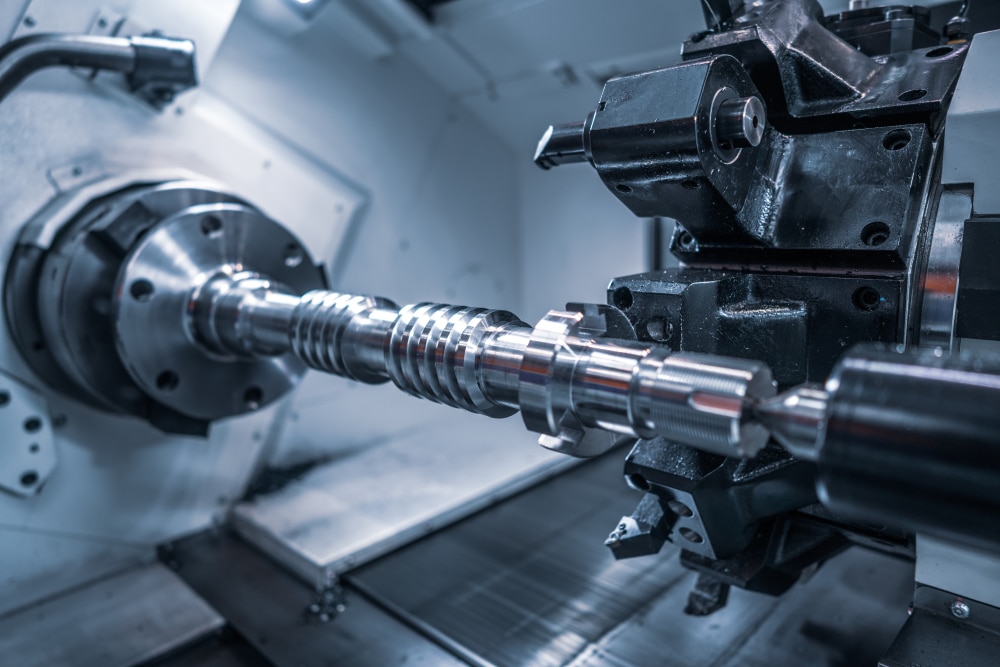

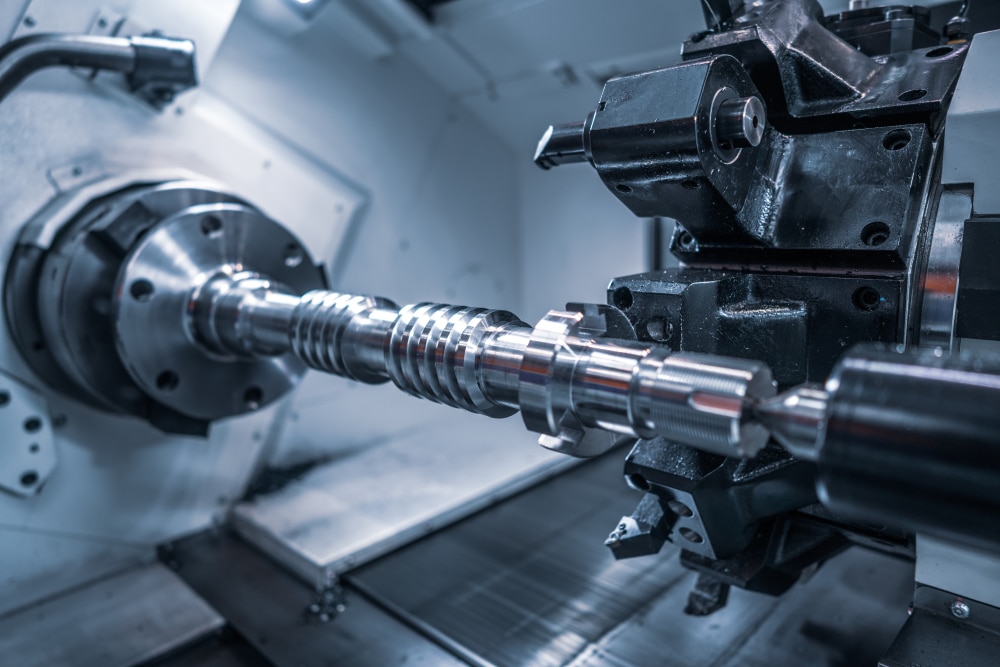

CNC swiss machining is a cost-effective and ultra-precise manufacturing process that can machine turned parts using a swiss CNC machine. CNC means computer numerical control, which refers to a computer unit that can control the machine with more tooling sets. So the equipment can perform different operations on the same piece due to the computer’s increased direction.

A CNC swiss screw machine has the same process. However, screw machining primarily involves removing material from a rotating piece. Furthermore, using a swiss machine CNC offers more benefits than other CNC manufacturing processes.

The Benefits of Using Swiss CNC Machines

Opting for Swiss CNC Machining instead of CNC swiss screw machining offers many advantages. It’s a prevalent technique that many manufacturers use today since its results are accurate and fast. Plus, it’s highly flexible.

Other benefits of Swiss CNC Machining are as follows:

- More tooling fixtures: More tooling fixtures are available, which can offer a double spindle feature.

- Time-saving: The more fixtures available, the more time the operator can save since it can create different cuts in one piece while only controlling a computer.

- Ideal for large-scale projects: Once the machine is pre-programmed and oriented with the desired pieces, it can run one part after the other. Thus, it is an ideal choice for large-scale projects with multiple parts requiring congruent measurements. Plus, one operator can supervise several machines at once.

- Do more precision work: Swiss CNC machining can do more precise work due to the tight, close quarters of the collet, tooling, and workpiece. So, it allows manufacturers to achieve their desired outcome.

These benefits make it an ideal option for small parts requiring precise measurements and intricate details. Many industries opt for swiss CNC machining compared to other methods.

Common Applications For Parts Made Through CNC Swiss Machining

In the industrial sector, most small parts are made through CNC swiss machines due to their low-cost factor. Plus, the process is faster. So it’s perfect for large-volume runs. Furthermore, it’s used in different sectors, such as IT, Agriculture, Automotive, Medical, Power, Consumer Electronics, and Aerospace.

Some of the most common applications are as follows:

- Surgical screws

- Medical devices

- Dental implants

- Scalpel

- Forceps

- Glasses

- Switches

- Connectors

- Springs

- Bearings

- Hubs

- Terminals

- Catalytic converters

- Mufflers

- Braces

- Splints

Many other specific products can be created and molded with the help of a swiss machine CNC. Above are just a few examples to give you an idea of what it can do.

Why Is It Ideal for Custom Solutions?

Since only some have the exact requirements, most manufacturers offer customized solutions using a CNC swiss machine. It’s the best option since they can get the specifications and design the customer wants and pre-program it onto the CNC unit. Plus, most manufacturers can adhere to the tight tolerances required for a specific item.

Choose Kernell’s Automatic Machining for Your CNC Swiss Machining Needs

We understand that every client is different. So we ensure that we have the best services to deliver quality products that exceed your expectations using a Swiss CNC Machine.

But if you have any questions or concerns, please contact us today. Or you can request a quote, and we’ll start your project immediately.

Kernell’s Automatic Machining is a leading products provider that serves a variety of industries with the help of exceptional Swiss CNC machining services. And one of these industries is the agricultural industry, which we have worked closely with for many years. With our in-depth knowledge of this sector, we can provide outstanding service that’s second to none.

We utilize cutting-edge Swiss machining CNC agriculture services that meet your expectations and the needs of even the most demanding projects. Therefore, we can design and develop tools and other products for their intended application while ensuring it works perfectly and according to your specifications.

Swiss CNC Machining for the Agriculture Industry

The agriculture industry refers to the art and science of cultivating soil to grow crops. Furthermore, raising livestock is also a part of agriculture. It’s composed of many elements, but the goal is to prepare the products from livestock and crops to be delivered to consumers to meet their demands.

However, many equipment, devices, tools, and systems ensure every project succeeds. Intricate parts are achieved through Swiss CNC machining, which is essential for even the most demanding applications. Therefore, Swiss CNC agriculture machining is the key to ensuring we produce quality results according to your specific requests and preferences.

What is Swiss CNC Machining?

Swiss CNC machining is controlled by a computer numerical control unit equipped with pre-programmed instructions. The instructions will direct the device and tooling to make the desired cuts, giving highly accurate results for even the most delicate and complex parts.

The main benefit of Swiss CNC machining is that less labor is required while producing large production runs. So even if numerous parts are needed, we can provide them promptly. Plus, the increased direction of the computer allows for more tooling sets. We can perform more operations on one workpiece in less time.

Other benefits of Swiss CNC Machining:

- High precision

- High production volume

- Create more complex designs

- Can make products with tight tolerances

- Eliminates the need for secondary operations

- Create small components in one cycle

- Excellent surface finish

- High repeatability

With the abovementioned advantages, many agricultural companies turn to us to create their parts or components through Swiss CNC machining. It’s a reliable, cost-effective method while developing small pieces with zero error.

Common Applications of Swiss CNC Machining for the Agriculture Industry

Since the agriculture industry uses different vehicles and equipment to perform their daily tasks, numerous parts are needed to ensure that the machines and systems operate correctly. And most of these parts are procured through Swiss CNC machining.

Applications of Swiss CNC machining for the agriculture industry

- Tractors

- Combine

- Harvester

- Balers

- Tractor attachments

- Miniature electronic connectors

- Valve parts

- Screws

These are only a few applications where Swiss CNC machining is vital. So you must choose this method to ensure that you receive parts only made for the application we will use for them. Otherwise, your project could fail, and you’ll suffer from a significant financial loss. But it’s our job to ensure that never happens through our state-of-the-art Swiss CNC machining equipment.

Trust Kernell’s Automatic Machining to Produce Quality Machined Parts

We know that the agriculture industry is more specific regarding its components. But we have the skills and expertise to ensure your demands are followed. Plus, our professional team ensures that your orders are promptly delivered.

So if you’re looking for a dependable Swiss CNC machining provider, trust Kernell’s Automatic Machine. Contact us today if you have any questions or concerns. Or request a quote, and we can start on your project immediately.